Thermal Imager

Fluke TiS75+

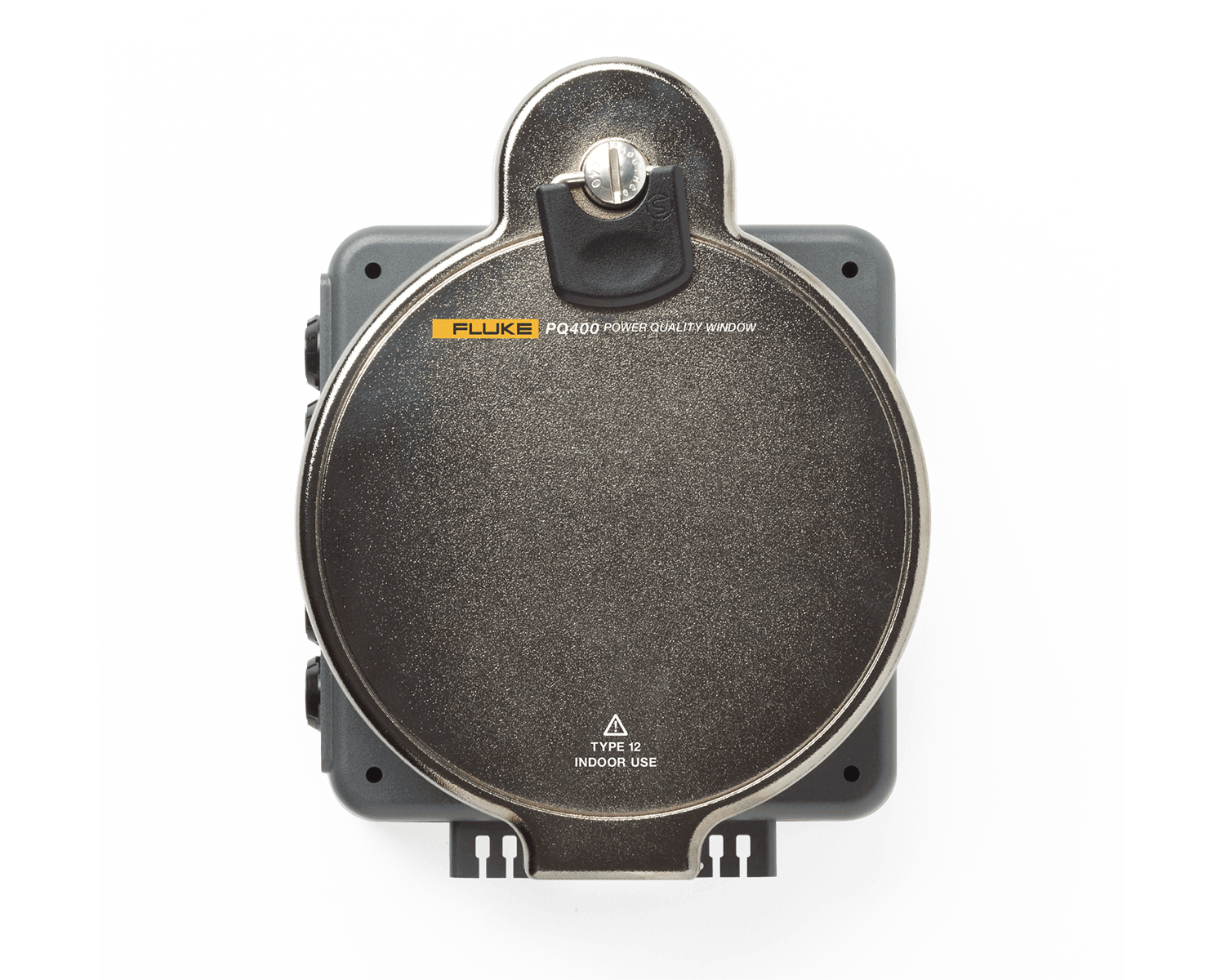

Electrical Measurement Window

Fluke PQ400

Infrared Window

Fluke CV300

Infrared Thermal Camera

Fluke Ti480U

Vibration Meter

Fluke 805 FC

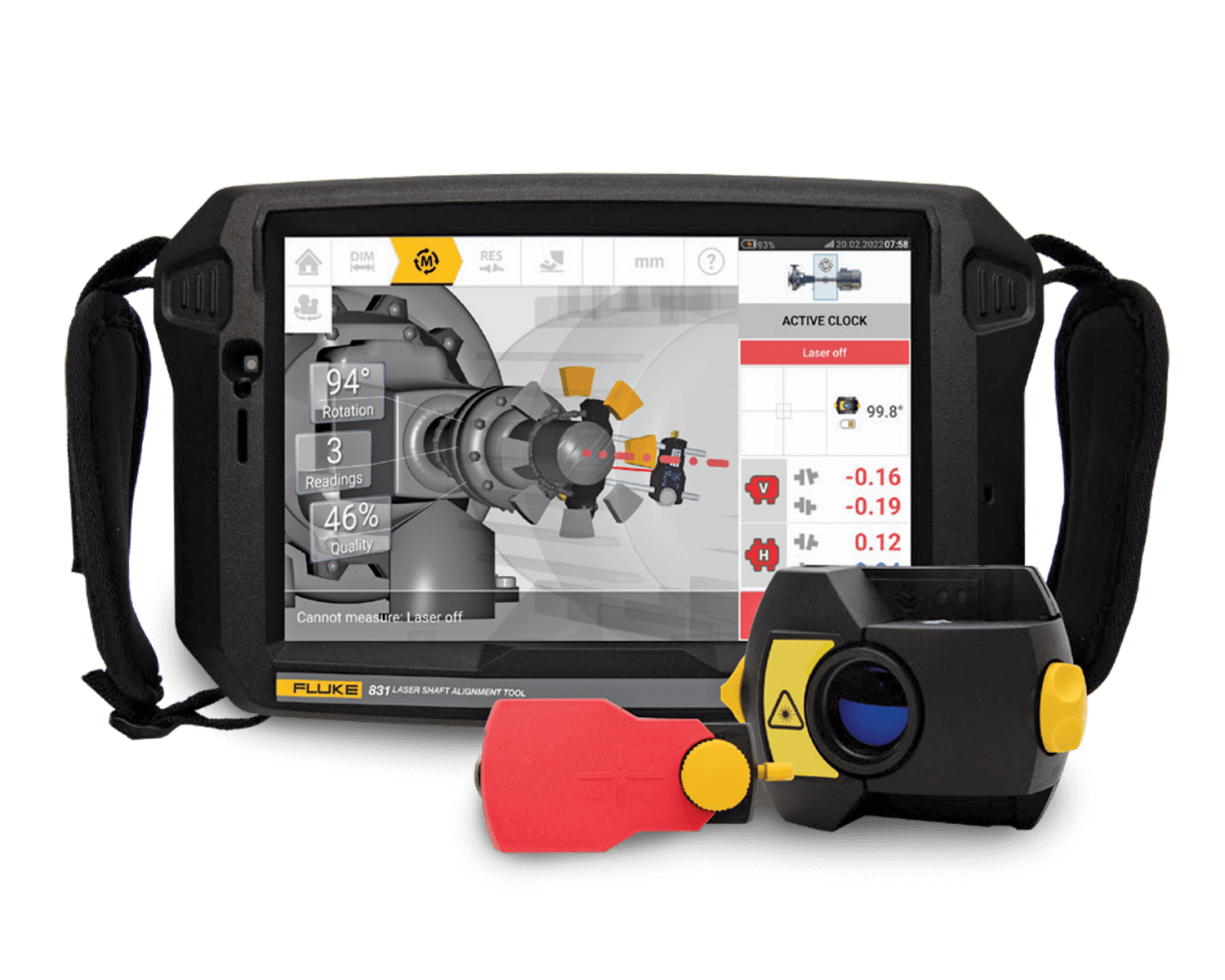

Laser Shaft Alignment Tool

Fluke 831

Vibration Tester

Fluke 810

Battery Analyser

Fluke BT521

Digital Multimeter

Fluke 87V MAX

Clamp Meter

Fluke 378 FC

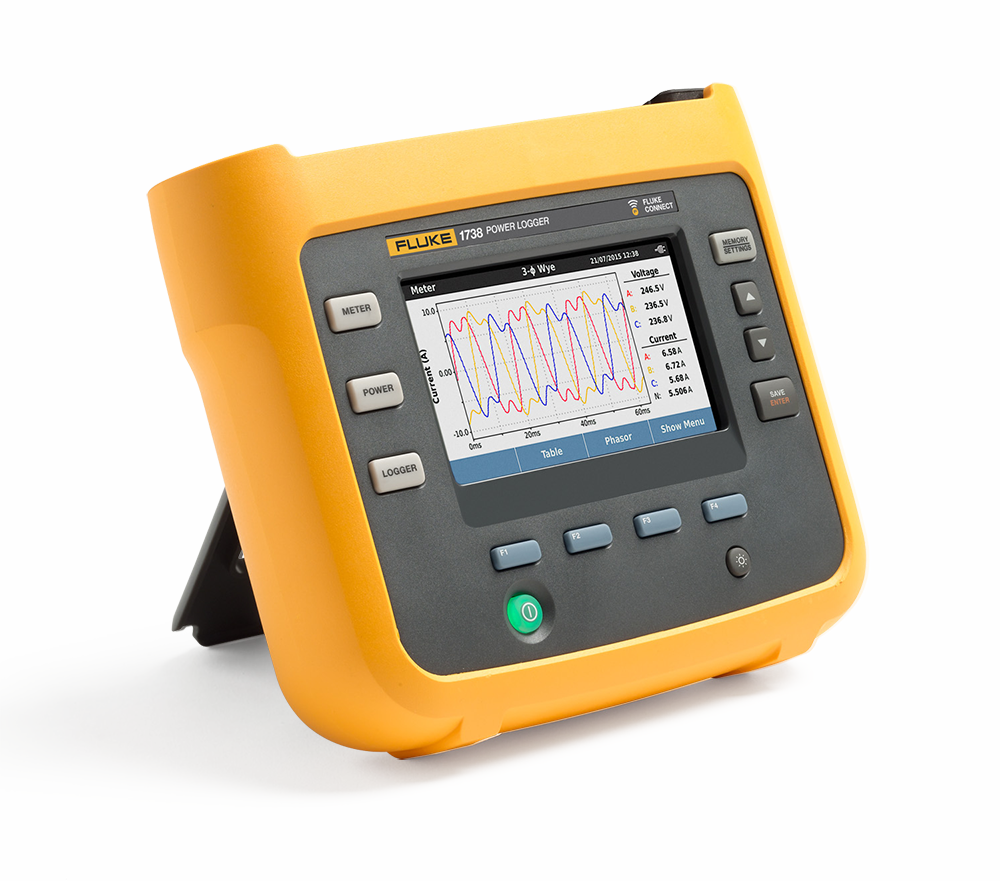

Power Quality Logger

Fluke 1738

Motor Drive Analyser

Fluke MDA-550 Series III

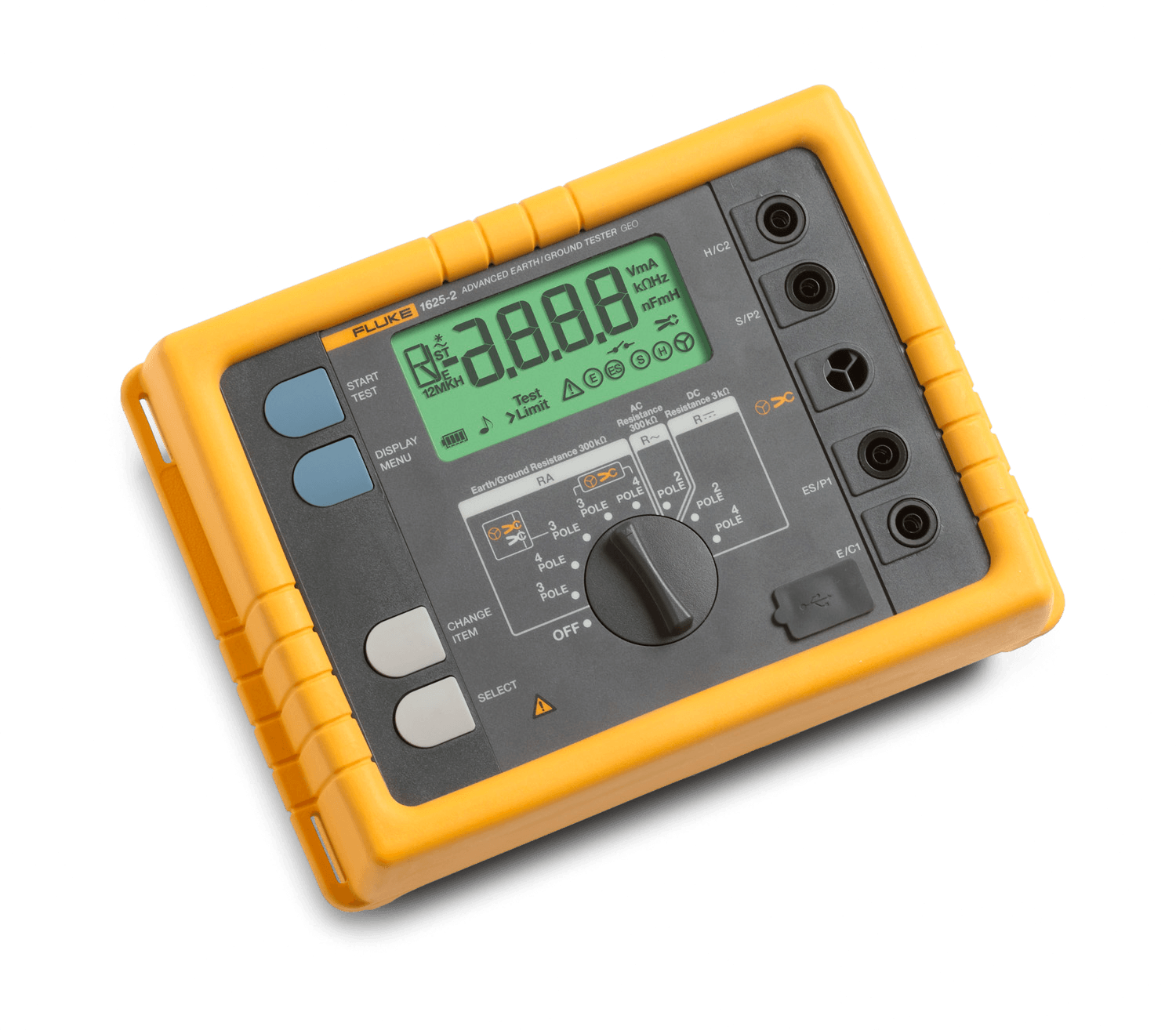

Earth Ground Tester

Fluke 1625-2

Insulation Multimeter

Fluke 1587 FC

Light Meter

Fluke 941

Sound Meter

Fluke 945

Vane Anemometer

Fluke 925

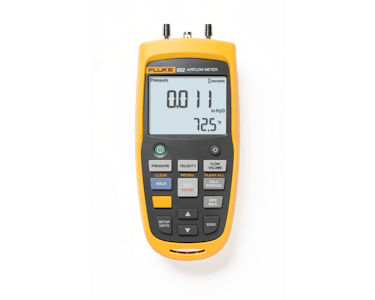

Micromanometer

Fluke 922

Temperature Humidity Meter

Fluke 972B

Power Quality Analyser

Fluke 1777

Infrared Thermal Camera

Fluke Ti300U

Milliamp Process Clamp Meter

Fluke 773

Automatic Pressure Calibrator

Fluke 729 PRO

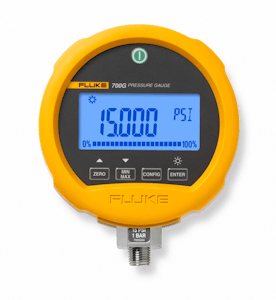

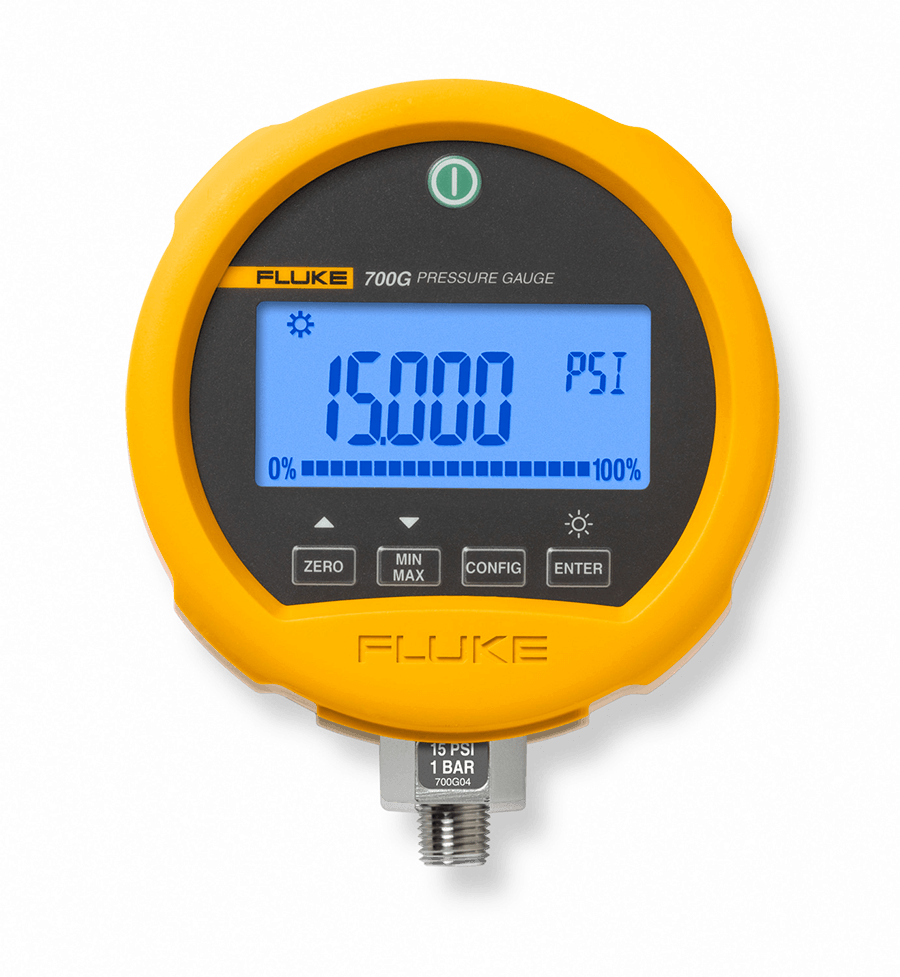

Pressure Gauge Calibrator

Fluke 700G

Precision Multifunction Calibrator

Fluke 726

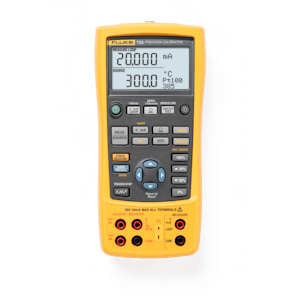

Documenting Process Calibrator

Fluke 754

Mounted Thermal Camera

Fluke RSE30/60

Acoustic Imager

Fluke ii900

Laser Belt Alignment Tool

Fluke 835

Thermal Camera

Fluke PTi120

IR Thermometer

Fluke VT08

Clamp Meter

Fluke 902 FC

Digital Multimeter

Fluke 116 HVAC

Precision Acoustic Imager

Fluke ii910 MecQ™

Conveyor maintenance must be efficient to avoid expensive, unplanned downtime. This is particularly important in industries like food and beverage production. The Fluke ii910 Precision Acoustic Imager with MecQ™ Mode provides a modern solution. It can detect potential problems in conveyor systems before they worsen. This allows maintenance teams to take proactive steps and maximize system performance.

Sees the sounds that could mean trouble in conveyor systems

Reduce outages and increase uptime

Reduce costs of maintaining conveyor system

Partial discharge is an issue that presents a significant potential hazard in Food and Beverage plant. If left unchecked it can result in catastrophic blackouts, fires, explosions, and ultimately monetary costs in unplanned downtime. The Fluke ii910 Precision Acoustic Imager enables you to locate partial and corona discharge in its earliest stages before it places your team and assets at risk.

Quickly and easily detect partial discharge, as well as compressed air, gas and vacuum leaks

Reduce outages and increase uptime

Use the PDQ Mode to capture and analyse partial discharge

Compressed air systems are used mainly in production line at Food and Beverage plant, but they can present a very serious potential hazard. The Fluke ii900 Acoustic Imager helps you locate air, gas, and vacuum leaks quickly and accurately by isolating the sound frequency of the leaks, helping you identify potential problems early before equipment failure.

Do more with the same air compressors and delay the capital expense of purchasing additional compressors

Improve reliability by ensuring proper air pressure to your pneumatic equipment

Reduce leak detection time and lower wasted energy costs

Thermal Imager

Fluke TiS75+

Electrical Measurement Window

Fluke PQ400

Infrared Window

Fluke CV300

Infrared Thermal Camera

Fluke Ti480U

Vibration Meter

Fluke 805 FC

Laser Shaft Alignment Tool

Fluke 831

Vibration Tester

Fluke 810

Battery Analyser

Fluke BT521

Digital Multimeter

Fluke 87V MAX

Clamp Meter

Fluke 378 FC

Power Quality Logger

Fluke 1738

Motor Drive Analyser

Fluke MDA-550 Series III

Earth Ground Tester

Fluke 1625-2

Insulation Multimeter

Fluke 1587 FC

Light Meter

Fluke 941

Sound Meter

Fluke 945

Vane Anemometer

Fluke 925

Micromanometer

Fluke 922

Temperature Humidity Meter

Fluke 972B

Power Quality Analyser

Fluke 1777

Infrared Thermal Camera

Fluke Ti300U

Milliamp Process Clamp Meter

Fluke 773

Automatic Pressure Calibrator

Fluke 729 PRO

Pressure Gauge Calibrator

Fluke 700G

Precision Multifunction Calibrator

Fluke 726

Documenting Process Calibrator

Fluke 754

Mounted Thermal Camera

Fluke RSE30/60

Acoustic Imager

Fluke ii900

Laser Belt Alignment Tool

Fluke 835

Thermal Camera

Fluke PTi120

IR Thermometer

Fluke VT08

Clamp Meter

Fluke 902 FC

Digital Multimeter

Fluke 116 HVAC